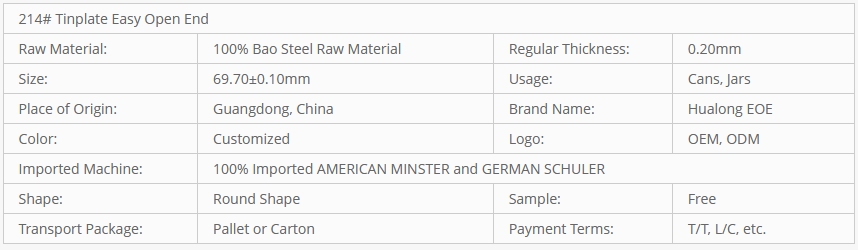

Professional China Tin Can End - 214# Tinplate Easy Open End (Epoxy Phenolic Lacquer – Clear Outside) – Hualong Detail:

Overview:

Description:

| Model No: | 214# |

| Diameter: | 69.70±0.10mm |

| Material: | Tinplate |

| General Thickness: | 0.20mm |

| Packing: | 84,000 Pcs /Pallet |

| Pallet Size: | 120 cm×100 cm×103 cm (Length×Width×Height) (cm) |

| Pcs/20′ft: | 1,680,000 Pcs /20′ft |

| Outside Lacquer: | Clear |

| Inside Lacquer: | Epoxy Phenolic Lacquer |

| Usage: | Used for cans which pack canned tomato paste, canned seeds, canned processed food, canned retorted food, canned dry foods, canned seasoning, canned fruit, canned beans and canned vegetables, etc. |

| Printing: | Base on customer’s requirement |

| Other Sizes: | 502#(d=126.5±0.10mm), 401#(d=99.00±0.10mm), 315#(d=95.60±0.10mm), 307#(d=83.50±0.10mm), 305#(d=80.50±0.10mm), 300#(d=72.90±0.10mm), 211#(d=65.48±0.10mm), 209#(d=62.47±0.10mm), 202#(d=52.40±0.10mm), 200#(d=49.55±0.10mm). |

Specifications:

|

214# |

Outside diameter (mm) |

Inside diameter (mm) |

Curl Height (mm) |

Countersink Depth (mm) |

|

79.2±0.10 |

69.70±0.10 |

1.9±0.10 |

4.8±0.10 |

|

|

Plane Depth (mm) |

Seaming Compound Weight (mg) |

Compressive Strength (kpa) |

Pop Force (N) |

Pull Force (N) |

|

3.90±0.10 |

61±10 |

≥240kpa |

15-30 |

50-70 |

Competitive Advantage:

CHINA HUALONG EOE CO., LTD., located in Jieyang, is a large easy open end manufacturer in easy open end producing field. Since establishment, we’re committed to the producing of aluminum and tinplate EOE products. Specialized in developing and producing round shape easy open end for over 18 years. Our product are widely used for packing canned food, with various sizes range from 50mm to 126.5mm, with more than 130 kinds of products. Multiple sets of easy open end production lines are whole new imported high speed fully automated equipment, including 8 sets of AMERICAN MINSTER and 2 sets of GERMAN SCHULER. Now the amount of annual output can reach over 4 billion pieces. Furthermore, Hualong EOE has qualified for the ISO9001 international quality system certification. Currently, 80% of our products are for export, and we have formed a stable marketing network covering the overseas market.

Product detail pictures:

Related Product Guide:

We emphasize progress and introduce new solutions into the market each year for Professional China Tin Can End - 214# Tinplate Easy Open End (Epoxy Phenolic Lacquer – Clear Outside) – Hualong, The product will supply to all over the world, such as: Iraq, Denver, Mauritius, Our factory covers an area of 12,000 square meters, and has a staff of 200 people, among which there are 5 technical executives. We are specialized in producing.We have rich experience in export. Welcome to contact us and your enquiry will be replied as soon as possible.

In our cooperated wholesalers, this company has the best quality and reasonable price, they are our first choice.

-

Reliable Supplier Vegetable Can - 300# TFS Bot...

-

Super Lowest Price Etp Lid - 401# TFS Easy Ope...

-

Hot Selling for Pet Food Cover - 307# TFS Easy...

-

Competitive Price for Plastic Can With Metal Li...

-

2022 Latest Design Bottom Cover - 209# TFS Eas...

-

Factory wholesale Poe End - 300# TFS Bottom En...