Professional China Tin Can End - 214# Tinplate Easy Open End (Epoxy Phenolic Lacquer – Clear Outside) – Hualong Detail:

Overview:

Description:

| Model No: | 214# |

| Diameter: | 69.70±0.10mm |

| Material: | Tinplate |

| General Thickness: | 0.20mm |

| Packing: | 84,000 Pcs /Pallet |

| Pallet Size: | 120 cm×100 cm×103 cm (Length×Width×Height) (cm) |

| Pcs/20′ft: | 1,680,000 Pcs /20′ft |

| Outside Lacquer: | Clear |

| Inside Lacquer: | Epoxy Phenolic Lacquer |

| Usage: | Used for cans which pack canned tomato paste, canned seeds, canned processed food, canned retorted food, canned dry foods, canned seasoning, canned fruit, canned beans and canned vegetables, etc. |

| Printing: | Base on customer’s requirement |

| Other Sizes: | 502#(d=126.5±0.10mm), 401#(d=99.00±0.10mm), 315#(d=95.60±0.10mm), 307#(d=83.50±0.10mm), 305#(d=80.50±0.10mm), 300#(d=72.90±0.10mm), 211#(d=65.48±0.10mm), 209#(d=62.47±0.10mm), 202#(d=52.40±0.10mm), 200#(d=49.55±0.10mm). |

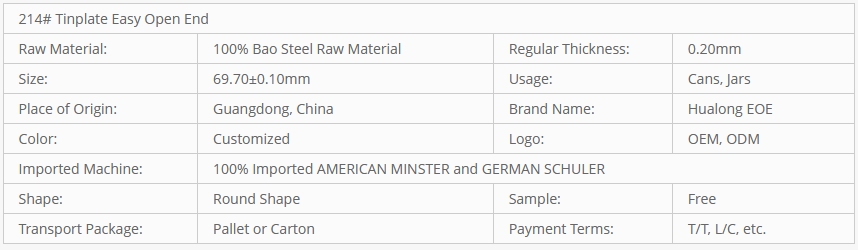

Specifications:

|

214# |

Outside diameter (mm) |

Inside diameter (mm) |

Curl Height (mm) |

Countersink Depth (mm) |

|

79.2±0.10 |

69.70±0.10 |

1.9±0.10 |

4.8±0.10 |

|

|

Plane Depth (mm) |

Seaming Compound Weight (mg) |

Compressive Strength (kpa) |

Pop Force (N) |

Pull Force (N) |

|

3.90±0.10 |

61±10 |

≥240kpa |

15-30 |

50-70 |

Competitive Advantage:

CHINA HUALONG EOE CO., LTD., located in Jieyang, is a large easy open end manufacturer in easy open end producing field. Since establishment, we’re committed to the producing of aluminum and tinplate EOE products. Specialized in developing and producing round shape easy open end for over 18 years. Our product are widely used for packing canned food, with various sizes range from 50mm to 126.5mm, with more than 130 kinds of products. Multiple sets of easy open end production lines are whole new imported high speed fully automated equipment, including 8 sets of AMERICAN MINSTER and 2 sets of GERMAN SCHULER. Now the amount of annual output can reach over 4 billion pieces. Furthermore, Hualong EOE has qualified for the ISO9001 international quality system certification. Currently, 80% of our products are for export, and we have formed a stable marketing network covering the overseas market.

Product detail pictures:

Related Product Guide:

With reliable excellent approach, great name and ideal consumer services, the series of products and solutions produced by our company are exported to many countries and regions for Professional China Tin Can End - 214# Tinplate Easy Open End (Epoxy Phenolic Lacquer – Clear Outside) – Hualong, The product will supply to all over the world, such as: Mauritania, Vietnam, America, Be sure to feel cost-free to send us your specs and we are going to respond for you asap. We have got a experienced engineering team to serve for the every single comprehensive needs. Free samples may be sent for yourself personally to know far more facts. So that you can meet your desires, please actually feel cost-free to contact us. You could send us emails and call us straight. Additionally, we welcome visits to our factory from all over the world for much better recognizing of our corporation. nd merchandise. In our trade with merchants of several countries, we often adhere to the principle of equality and mutual advantage. It is our hope to market, by joint efforts, both trade and friendship to our mutual benefit. We look forward to getting your inquiries.

Good quality, reasonable prices, rich variety and perfect after-sales service, it's nice!